Exclusive distributor of PIX Belts since 1989

Catering for industries from ceramics to packaging machinery, the range provides solutions for virtually every drive belt application in current use. PIX also have a long history of developing bespoke drive belt solutions for OEMs across the globe.

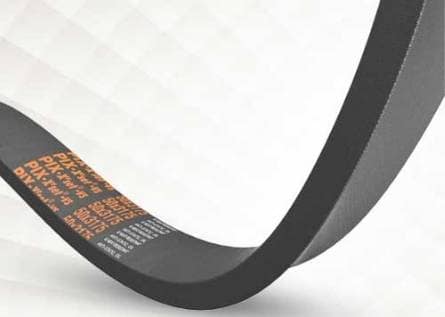

VARIABLE SPEED WRAPPED BELTS

PIX produce a huge range of variable speed belts, to suit everything from combine harvesters to gym treadmills.

These belts operate between variable speed pulleys allowing the speed of the driven pulley to alter by either changing the centre distance between the pulleys or varying the width of the pulley.

These belts feature a wear-resistant bias-cut neoprene-rubberized poly-cotton fabric cover, with high tenacity, low-stretch polyester cords, and high-modulus compression rubber.

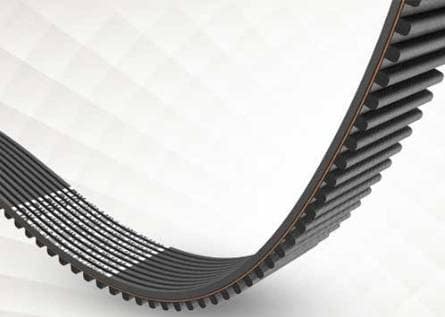

VARIABLE-SPEED, MOULDED RAW EDGE COGGED BELTS

Cogged variable speed belts perform a similar function to X’set VS wrapped VS belts.

The raw-edge construction does, however, give superior grip resulting in less slippage. They also have a longer service life, increased flexibility, and will work in a higher temperature range of -25°C to +100°C.

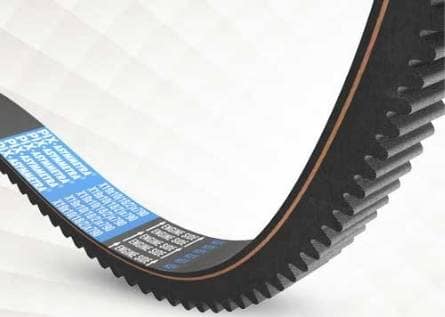

MOULDED RAW EDGED COGGED, VARIABLE SPEED BELT

PowerTex-XV2 was originally developed to meet the high-power transmission requirements of textile machinery and spinning machines.

PowerTex is available in the commonly used sizes in the textile industry, and features:

• Aramid cords.

• Moulded Cogged for flexibility

• CR-impregnated cotton/polyester top fabric jacketing.

• Specially compounded cushion rubber.

• Fibre-filled polychloroprene base compound.

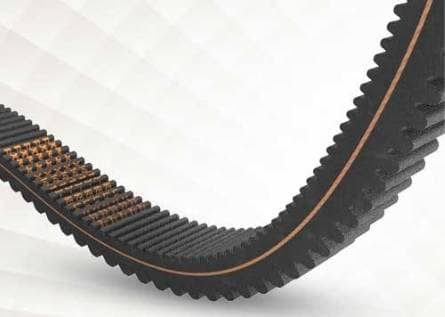

DOUBLE-COG, VARIABLE-SPEED MOULDED RAW EDGE COGGED BELTS

Duo-XV is a highly flexible belt, and able to operate smoothly on smaller pulleys.

The double cog feature also improves the heat dissipation rate, and these belts will operate in temperatures from -25°C to +100°C.

RAW-EDGE LAMINATED BELTS

Used on applications where there is a relatively high power, with high wear resistance, and high flexibility.

The multi-layers of fabric and fibre-filled base compound prevent cracking, at the bottom of the profile, when the belt is bent back on itself.

The product works well with back idlers and works in a temperature range from -25°C to +100°C.

PACKAGING MACHINERY POLY V-BELTS

TopCoat XC are constructed with a Poly-V belt drive component backed with a profiled top made of application-specific rubber.

The topcoat selection is based on the temperature and Shore hardness required and can be 4, 6, 8, or 10mm thick.

The Poly-V drive member is vulcanised with the top coat as a single piece and is available in PJ, PK, or PL sections.

The profile top is used to grip and cushion various material in conveying and packaging processes. Typically found in bottling plants, packing conveyors, extruding machinery, etc.

PACKAGING MACHINERY TIMING BELTS

TopCoat XT are constructed with a timing belt drive component backed with a profile top made of application-specific rubber.

The topcoat selection is based on the temperature and Shore hardness required and can be 4, 6, 8, or 10mm thick.

The timing belt drive member is vulcanised with the top coat as a single piece and is available in L, H, 5M, S5M, 8M, S8M profiles.

The profile top is used to grip and cushion various material in conveying and packaging processes. Typically found in vertical form fill seal (VFFS) machines, ceramics industry, packaging lines etc.

HYBRID POLY-TIMING BELTS

Brawn-XT was primarily developed for the milling industry, and it is regularly found in flour and rice mills.

The belt is a double-sided drive belt, having timing belt teeth on one side and Poly-V ribs on the other. To bolster the tensile strength for this application, the belts are Aramid-corded and made with specific heat and abrasion-resistant compounds. Working temperature is from -35°C to +130°C.

Ribbed profiles available – PK and PL.Timing profiles available – 5M, 8M, S8M

PROFILE-TOP WRAPPED BELTS

Echelon belts are a range of Classical belts with a top profile of specially compounded rubber vulcanised to the belt cover.

The belts are used to convey material on the belt back, whilst simultaneously transmitting power through the ‘V’ section.

The material in the profile top can be chosen depending on the application.

PROFILE-TOP WRAPPED BELTS

Ceramica belts are a range of Classical belts with a triangular top-profile of specially compounded rubber vulcanised to the belt cover.

As the name would suggest, these belts were originally produced for the ceramics industry, and convey material on the belt back, whilst simultaneously transmitting power through the ‘V’ section.

The material in the profile top can be chosen dependant on the application.

Available in B and C sections.

ROOT HARVESTER LIFTING BELTS

ROOT HARVESTER LIFTING BELTS

Extractor-XS was designed to do very much as the name suggests – extracting root crops in arable farming.

Another in the range of profile top belts produced by PIX, it features triangular serrations across the belt. Used in pairs, the Belts actually grip the haulms of the crop and lift them up into the harvester.

Used mainly for carrot and beet harvesters.

Available in D and 37mm sections.

LOW TEMPERATURE WRAPPED BELTS

Igloo-XS is a high-performance wrapped belt made with special materials which allow it to operate at very low temperatures – temperature range -45°C to +80°C.

The special compounds used allow the belts to remain flexible, and avoid cracking in low-temperature applications such as cooling tunnels, cold storage rooms, etc.

SCOOTER VARIABLE SPED BELTS (CVT)

High-power, variable speed belt built for CVT drives, such as those found in motor scooters.

With EPDM-treated cords and fibre-loaded EPDM compression rubber, the belts provide a smooth variable speed drive at high temperatures, with minimal stretch.

BELTS FOR CVT DRIVES, ATVS & ELECTRIC VEHICLES

Superior construction to sustain high-torque, vari-speed, applications under extreme operating conditions.

Available in three different series, dependant on application requirement, including the XX section which is double-sided cogged.

ASYMMETRIC CVT BELTS

A constantly variable transmission belt which is commonly found on Go-karts, snowmobiles, and materials handling equipment.

The belts have a much more acute angle (2°) on one side of the belt compared to the other (18°).

Asymmetra-XV have Aramid cords, giving minimal stretch and enhanced shock-absorbing capacity; and are made using a special adhesion compound for improved dynamic adhesion.

PROFILE-TOP WRAPPED BELTS

Textura belts are a form of profile top Classical belt which feature a layer of ‘soft’, ‘honey-comb’ rubber material vulcanised to the back of the V-belt.

Textura is used in conveying applications, particularly where the material needs careful handling. This type of belt is extensively used in the ceramic, food and drink industries.

Available in B and C sections.

Our super talented Technical team are continuously working on simplifying techniques, providing innovative new products and providing 3D models to help our customers get what they need. Our Technical Hub will provide you with detailed information which will help you design and decide on the products you may need.

While every effort is made for you to make that decision, our Engineers are always on-hand to help.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |