TUBE BENDING

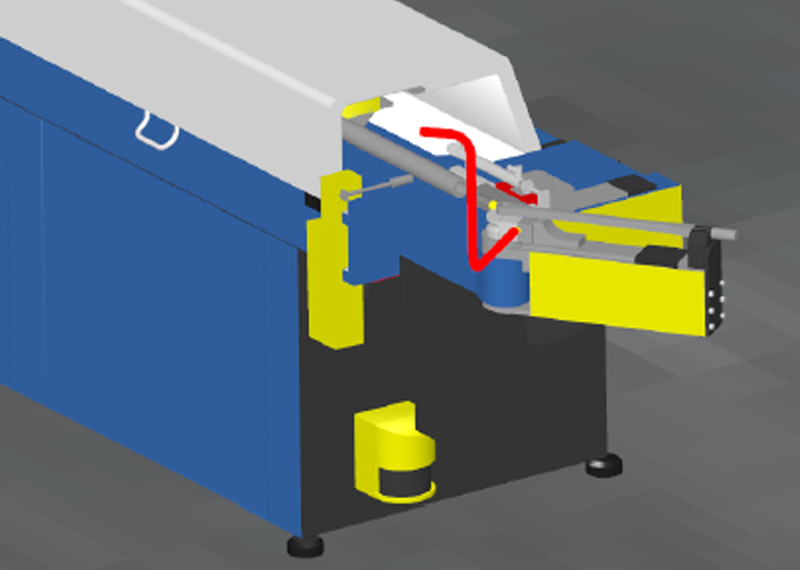

Tube bending capacity on both our CNC machine and is semi-automatic machine 6mm OD to 42mm OD.

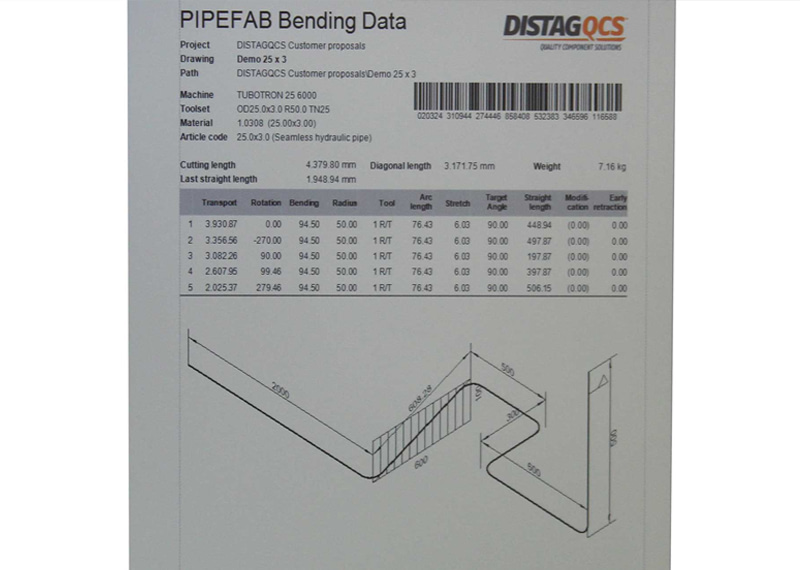

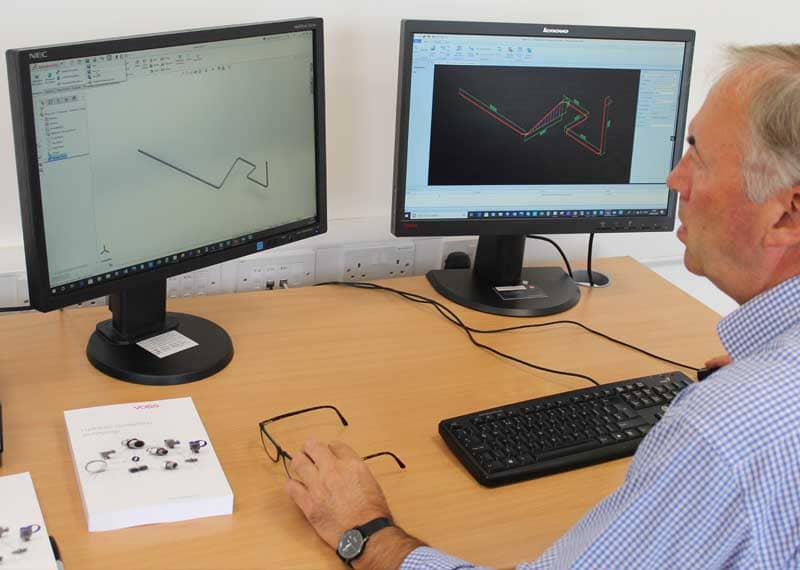

BESPOKE SOFTWARE FOR MAXIMUM ACCURACY & CONSISTENCY FOR LOW-MEDIUM BATCHES

For fast turnaround Distag QCS utilise Barcode data uploader on low-medium volume batches.

For fast turnaround Distag QCS utilise Barcode data uploader on low-medium volume batches.

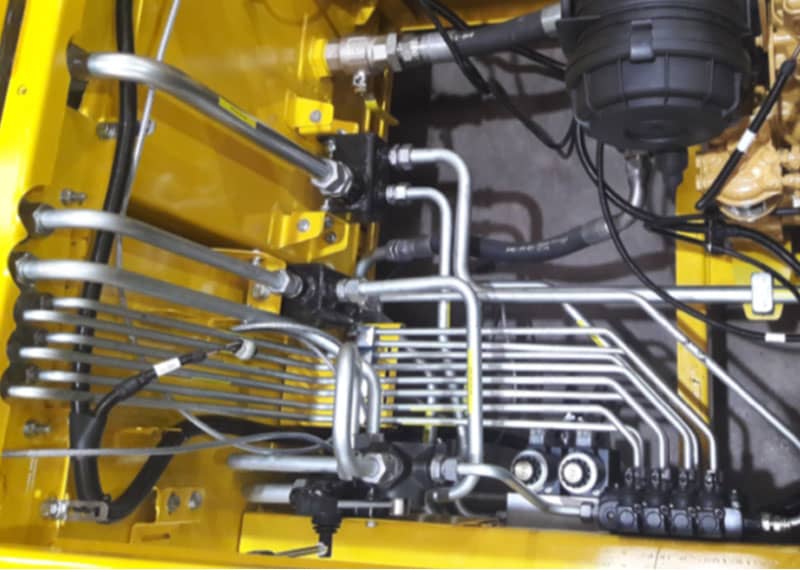

When designing a Hydraulic Steel Tube assembly, it is critical to select the correct tube specification for the application, Distag QCS offers two types of hydraulic tube grades based on customers’ requirements.

Distag QCS Hydraulic Steel assemblies are typically produced using Seamless Cold Drawn Hydraulic Linepipe according to EN10305-4 (DIN 2445/2). (CR 6 Free Electrolytic galvanised). The tube has the following specifications; Grade: E235 Yieldstrenght: <16mm =235N/mm2 >16<40 225N/mm2 >40 <65 215N/mm2 See below for standard stock sizes available from Distag QCS

As a leading supplier of complete port-to-port solutions, at Distag QCS Group we offer a comprehensive range of fluid power components, including tube connection systems, hydraulic hose, fittings, assemblies, kits, motors, cylinders, valves, and accessories. The range includes FLEXEPULSE hose, FLEXEQUIP and VOSS tube and end-fittings.

Distag QCS (UK) Ltd, previously known as Flexequip Ltd, was founded in July 1971 and began manufacturing hydraulic couplings to service a large home and export market across the world through a distribution network.

The Flexequip brand has been synonymous with designing and manufacturing high-quality hydraulic couplings for over 50 years. From the early days of re-usable couplings, and braised adapters, to the current range of one & two-piece fittings, the FH logo is widely recognised across Europe, UK, and the Middle East.

Following the acquisition by the Distag group in 2006, the company has continued to expand the product range and service provided, and today we carry over 10,000 active hydraulic component SKUs, including hose, fittings, adapters, QR couplings, valves, motors, cylinders, clamps & hose protection.

In addition to the components provided, Distag also manufacture hose assemblies, manipulated steel tube assemblies, and build hydraulic kits according to customer specification.

While the name may have changed, and the product range expanded, we are proud to have some members of the team still with us today, who have been on this journey with the company for over 30 and 40 years; and witnessed the continuous development and improvement in hydraulic couplings.

We welcome you to take a look at our new celebration catalogue, and see some of the products which will take us into next 50 years phase.

Our super talented Technical team are continuously working on simplifying techniques, providing innovative new products and providing 3D models to help our customers get what they need. Our Technical Hub will provide you with detailed information which will help you design and decide on the products you may need.

While every effort is made for you to make that decision, our Engineers are always on-hand to help.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |