TIMING BELTS ARE BECOMING INCREASINGLY PREVALENT IN MODERN DRIVE SYSTEMS, PARTICULARLY WITH THE GROWTH OF AUTOMATION.

Timing Belts can be best described as having integrally moulded teeth on the internal circumference, which make positive engagement with axially grooved pulleys. Timing belts are also known as Synchronous, or Positive-Drive, belts. The most important feature of a synchronous drive is that it offers a fixed speed ratio between the driver and the driven pulleys.

Other important characteristics include:

PIX timing belts are produced in their new, state-of-the-art TRP Plant, near Nagpur.

STD (SUPER TORQUE DRIVE) PROFILE TIMING BELTS

STD (Super Torque Drive) Profile Timing Belts.

STD belts have a modified tooth profile which gives a more positive engagement with the pulleys. This results in the forces being distributed more evenly throughout the tooth, giving longer belt life, and reducing the likelihood of teeth shearing off.STD belts are available in S2M, S3M, S5M, S8M and S14M profiles.

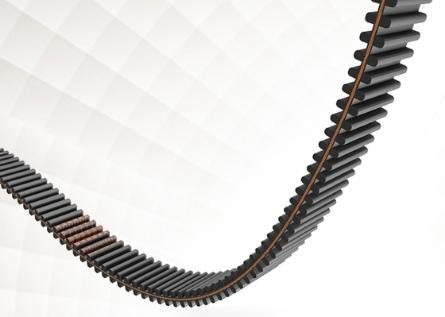

DOUBLE-SIDED TIMING BELTS

Now used extensively in textile units, printing and packaging machines; but the most common application would be for mower decks. See DS Timing Belts in Lawn & Garden section for more details.

HYBRID POLY-TIMING BELTS

Brawn-XT was primarily developed for the milling industry, and it is regularly found in flour and rice mills.

The belt is a double-sided drive belt, having timing belt teeth on one side and Poly-V ribs on the other. To bolster the tensile strength for this application, the belts are Aramid-corded and made with specific heat and abrasion-resistant compounds. Working temperature is from -35°C to +130°C. Ribbed profiles available – PK and PL. Timing profiles available – 5M, 8M, S8M

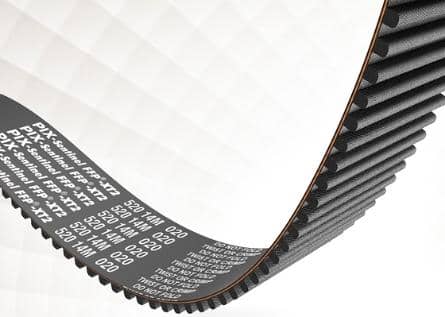

HIGH-POWER, HARSH ENVIRONMENT, TIMING BELT

Known in the industry as a Fin-Fan belt, Sentinel was developed to power Air-Cooled Heat Exchangers (ACHEs) – always regarded as one of the harshest environments for synchronous belt to operate in.

As well as having a higher power transmission capacity and higher tensile strength, these belts has impressive abrasion-resistant qualities.

PACKAGING MACHINERY TIMING BELTS

TopCoat XT is constructed with a timing belt drive component backed with a profile top made of application-specific rubber. The topcoat selection is based on the temperature and Shore hardness required and can be 4, 6, 8, or 10mm tick. The timing belt drive member is vulcanised with the top coat as a single piece and is available in L, H, 5M, S5M, 8M, S8M profiles.

The profile top is used to grip and cushion various material in conveying and packaging processes. Typically found in vertical form fill seal (VFFS) machines, ceramics industry, packaging lines etc.

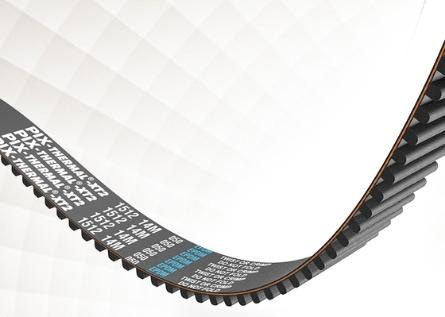

HIGH-POWER, HIGH TEMPERATURE, TIMING BELTS

As well as having an extreme working temperature range, up to 130°C, Thermal-XT2 has a higher power transmission capacity compared to TorquePlus-XT2. It will run at higher angular speeds, is resistant to Ozone, and has very low noise characteristics.These belts are available in 5M, S5M, 8M, S8M, and 14M sections

Our super talented Technical team are continuously working on simplifying techniques, providing innovative new products and providing 3D models to help our customers get what they need. Our Technical Hub will provide you with detailed information which will help you design and decide on the products you may need.

While every effort is made for you to make that decision, our Engineers are always on-hand to help.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |