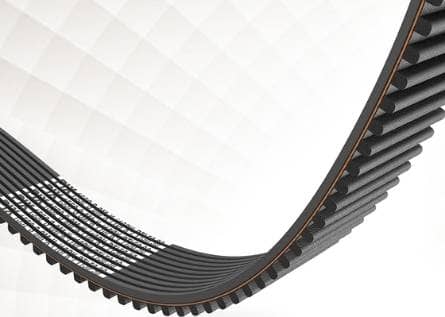

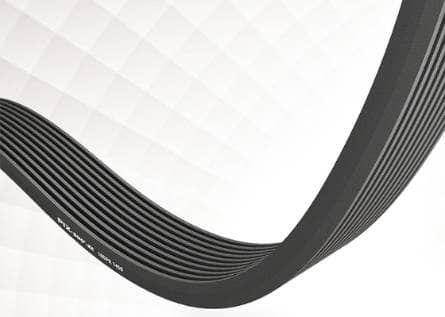

Multi Ribbed or Poly V-Belts are an IDEAL SOLUTION TO COMPACT DRIVES IN HOUSEHOLD APPLIANCES; AUTOMOTIVE DRIVES; AGRICULTURAL MACHINERY; LAWN & GARDEN EQUIPMENT; AND MANY OTHER APPLICATIONS IN GENERAL INDUSTRY.

Multi Ribbed Belts combine the high flexibility of flat Belts with a higher-power transmission capacity than the traditional V -Belt. Multi Ribbed Belts enable economic solutions even under difficult drive conditions, such as large transmission ratios, high belt speeds, small diameter pulleys and drives with back idler pulleys. The belts consist of multiple V-ribs that mesh into the groves of the pulley.

PIX-X’ceed® Multi Ribbed Belts are available in PH, PJ, PK, PL and PM profiles. As well as the standard versions, these belts are also available in High Temperature; Elasticated; Topcoat (for packaging machinery); FRAS (Fire-Resistant, Anti-Static); and Double-Sided derivatives.

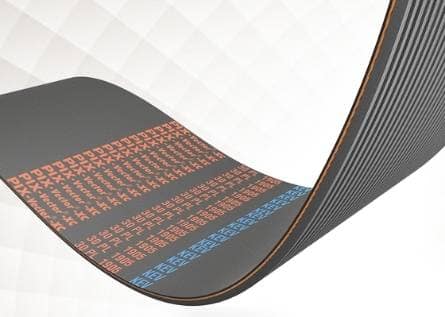

HYBRID POLY-TIMING BELTS

Brawn-XT was primarily developed for the milling industry, and it is regularly found in flour and rice mills.The belt is a double-sided drive belt, having timing belt teeth on one side and Poly-V ribs on the other. To bolster the tensile strength for this application, the belts are Aramid-corded and made with specific heat and abrasion-resistant compounds. Working temperature is from -35°C to +130°C.Ribbed profiles available – PK and PL.Timing profiles available – 5M, 8M, S8M

PACKAGING MACHINERY POLY V-BELTS

TopCoat XC are constructed with a Poly-V belt drive component backed with a profiled top made of application-specific rubber.The topcoat selection is based on the temperature and Shore hardness required and can be 4, 6, 8, or 10mm thick. The Poly-V drive member is vulcanised with the top coat as a single piece and is available in PJ, PK, or PL sections.The profile top is used to grip and cushion various material in conveying and packaging processes. Typically found in bottling plants, packing conveyors, extruding machinery, etc.

HIGH TEMPERATURE POLY V-BELTS

There are many mowers, domestic appliances, and small machines that now require a compact Poly-V drive, but run at very high temperatures. Thermal-XC features EPDM Polyester tension members, along with fibre-loaded EPDM compression, giving high thermal resistance, minimum elongation, and enhanced dimensional stability. Operating temperature of -35°C to +130°C

DOUBLE-SIDED POLY- V-BELTS

Most commonly recognised as the VW Beetle fan belt type, Duo-XC is now used in many applications from textile machinery to flour mills. These belts transmit power on both sides and are normally used in quite complex ‘serpentine’ drives.Normally produced in PK section.

HIGH-POWER, ARAMID-CORDED POLY V-BELTS

Vector is a truly spectacular performer, with a huge power handling capacity, high tensile strength, and high frictional grip for maximum traction.Originally developed to drive helicopter rotors, it is also highly flexible, virtually noise-free, and vibration resistant.Normally supplied in PL section, this product is finding many more applications, where it often replaces sets of v-belts.

POLYSTRETCH-XC ELASTICATED POLY V-BELTS

There is a growing requirement for Poly-V belts which have the ability to stretch but maintain their dimensional stability – in effect to self-tension. In many applications now, such as small lawnmowers, domestic appliances etc., the pulleys are static, and the belt has to be, in effect, stretched over them to fit. A specially designed Polyamide tension member allows the belt to maintain uniform tension throughout the life of the belt. These belts will operate between -25° and +100°C and, as the ribs are able to keep optimum contact area, they have a higher power transmission rating.

Our super talented Technical team are continuously working on simplifying techniques, providing innovative new products and providing 3D models to help our customers get what they need. Our Technical Hub will provide you with detailed information which will help you design and decide on the products you may need.

While every effort is made for you to make that decision, our Engineers are always on-hand to help.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |